Pump Design

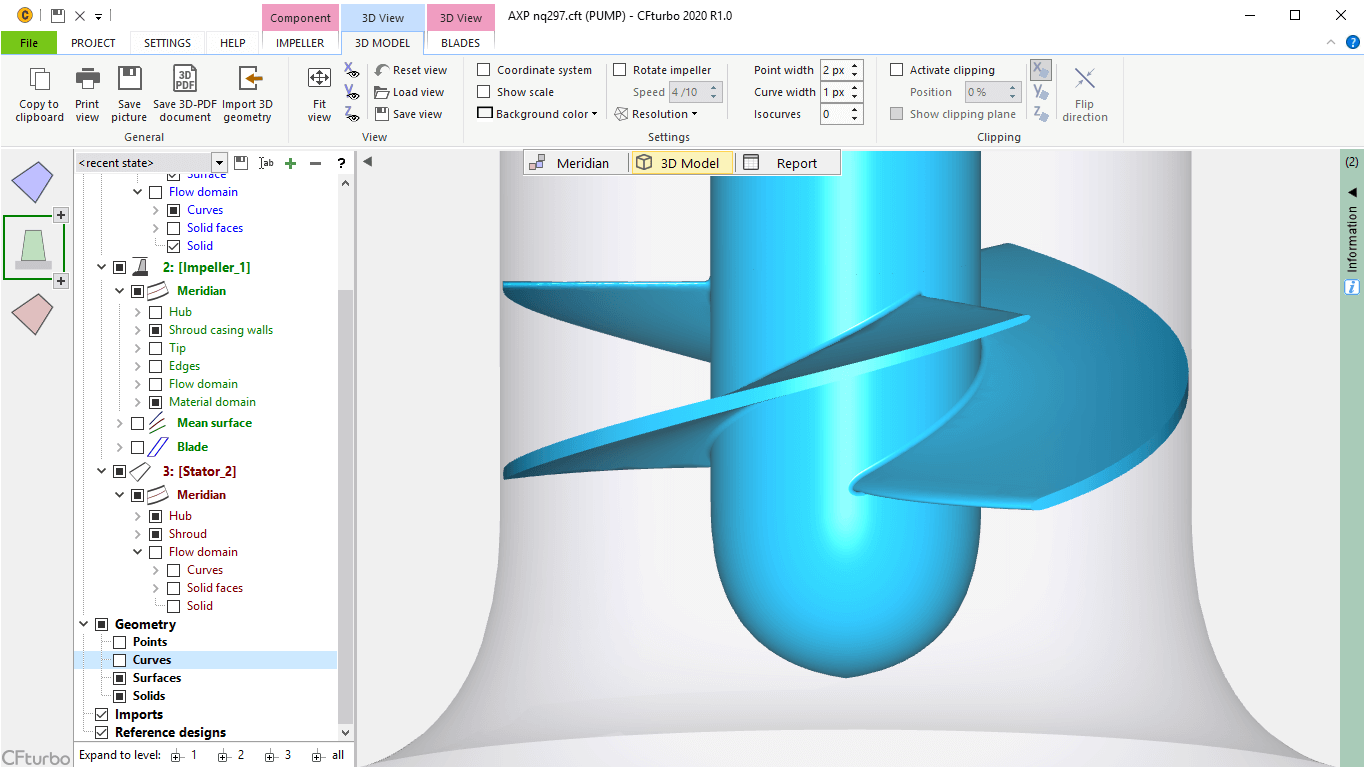

Capabilities

- Design different types of pumps in a specific speed range 8 < nq < 500 (EU), 400 < Ns < 22,000 (US)

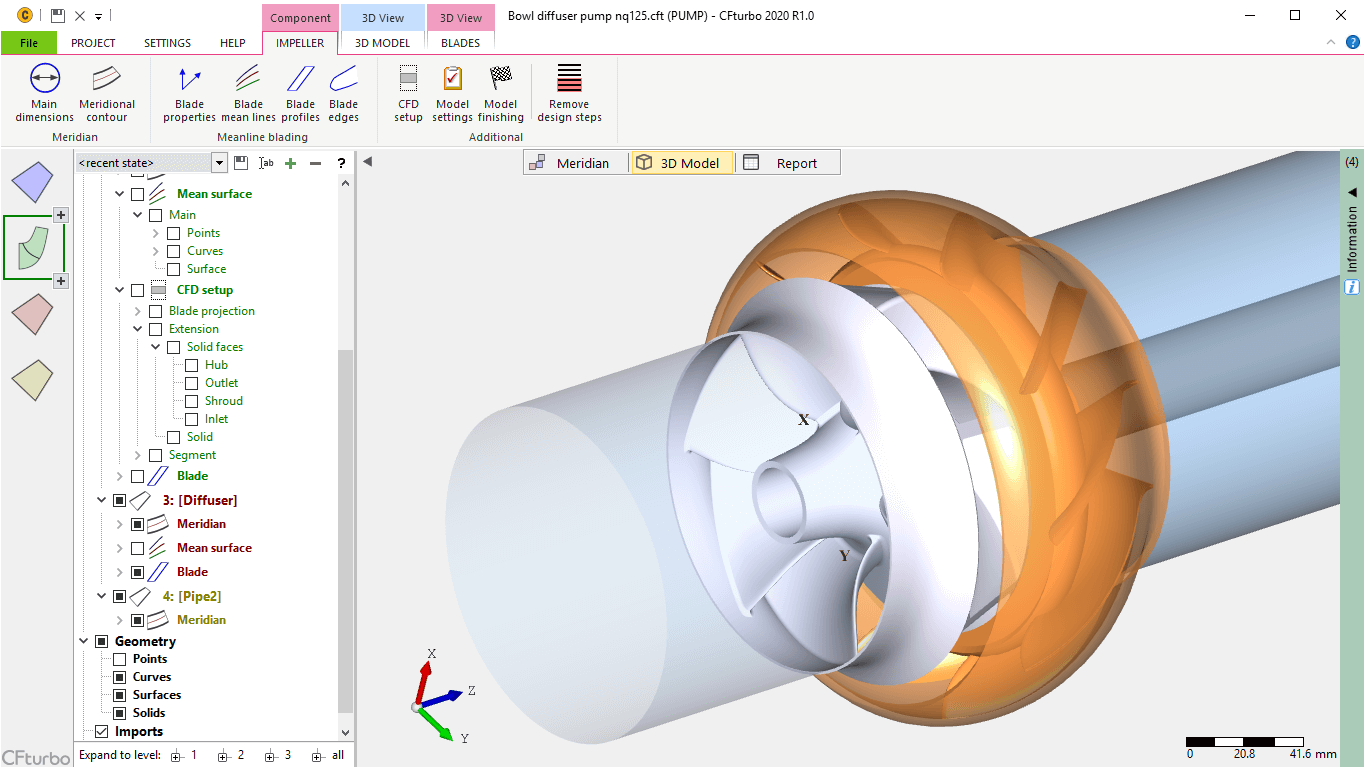

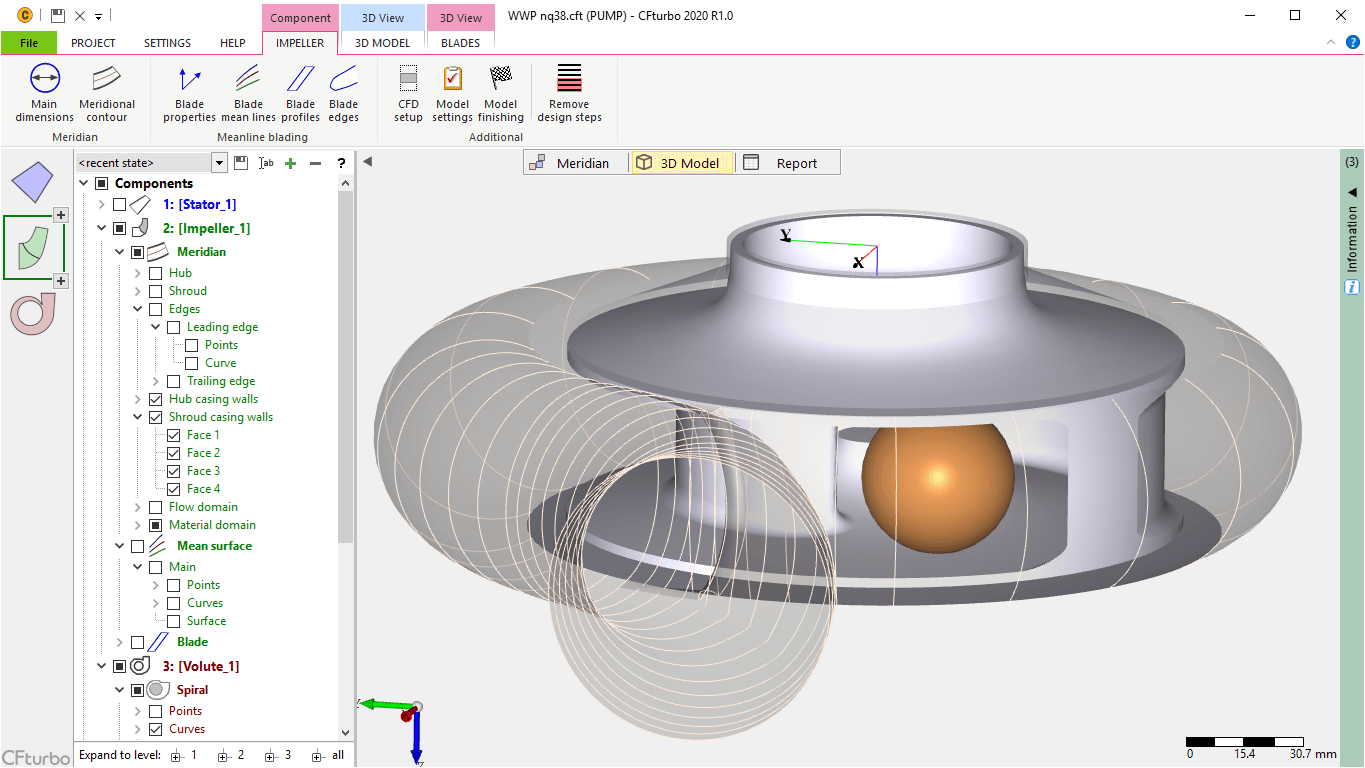

- Create complete pump stages from different single components such as impellers, vaned and vaneless stators, and volutes

- Use a fully parametric geometry model of the pump that can be the basis for design exploration and optimization

- Export the 3D model for further applications like flow simulation (CFD), finite element analysis (FEA), mechanical design (CAD), and rapid prototyping

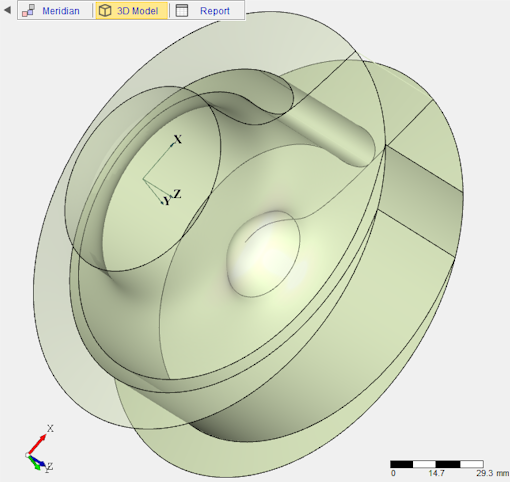

Impellers

Design pump impellers according to your specific needs. The underlying design theory is based on fundemental equations and the latest empirical correlations.

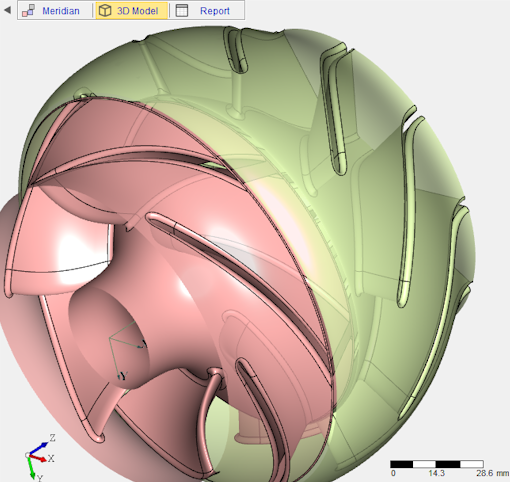

Volutes

Design the volute while the pump type is centrifugal. Outflow conditions of the previously designed impeller or radial diffuser are automatically taken into account.

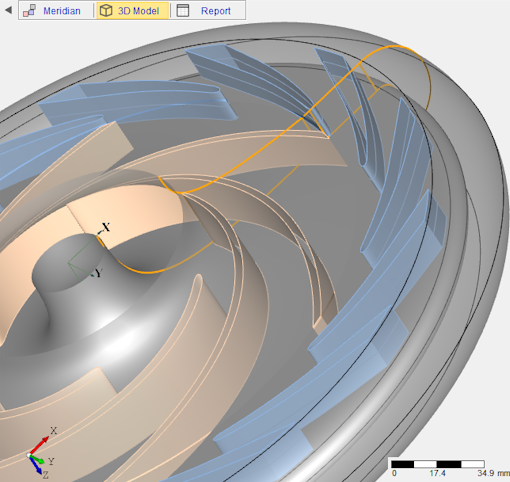

Stators

Vaned and unvaned stators complete the flow channel of the pump stage. Additionally, unvaned stators may be used to prepare a model for flow simulation.

Optimize your pumps

Through the connection of simulation software you can partially or completely automate your workflow to optimize your pump. This will significantly reduce development time.